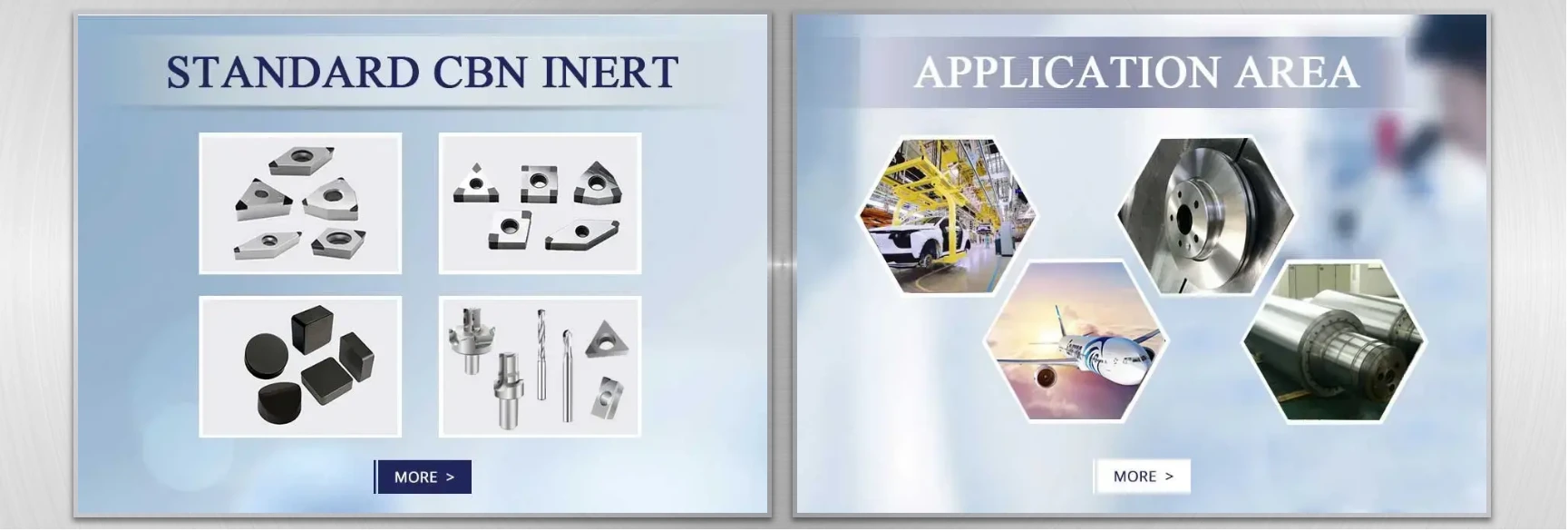

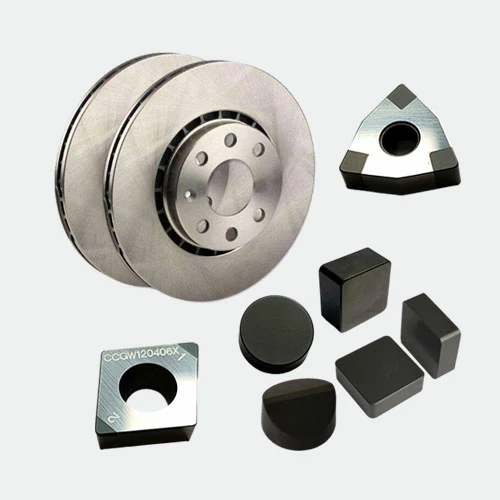

Product Center

We have established long-term cooperative relations with many enterprises.

Product Application

Warmly welcome friends from all walks of life to visit, investigate and negotiate business!

About Us

Leading CBN cutting tool manufacturer since 1998

Henan WEGCL New Materials Co., Ltd. (Named SCBN TOOLS), originated from China Henan New Materials Research Institute (formerly a comprehensive materials research institution directly under the Ministry of Machinery Industry of China), focusing on the research and development and production of superhard materials, is committed to providing the best cutting solutions and tools for global customers, and is regarded by customers as a reliable supplier of superhard material tools. After several years of rapid development, SCBN TOOLS has formed an industrial pattern based on the advantages of raw materials and turning tools, and has realized the self-sufficiency of the whole industry chain. In the application technology and material research···

-

+

Factory land occupation

-

+

Senior technical engineer

-

+

Utility model patent

-

+

Global customers

News Center

Official certification, professional after sales service.

2022-Jul-08

Hardenedsteel is a common type of steel with increased hardness after quenching in machining workshops. There are many types of hardened steel workpieces, and there are many processing difficulties during the processing.The machining of hardened steel involves many different machining conditio

2022-Jul-02

IntroductionAisi 630 steel is a high-strength, heat-treatable alloy that is commonly used in a variety of industries. When it comes time to cut this tough material, you want to make sure you have the right tools for the job. In this article, we'll walk you through some of the best cutting tools

2022-Jun-22

When Processing heat treat d2 steel, pcbn inserts are useful. They improve the quality of the resulting steel by controlling the tempering process. What are pcbn inserts? pcbn inserts are small, cylindrical objects that are inserted into the cooling channel of a heat treat fu

2022-Jun-16

Google Inc. has announced a larger version of its Nexus tablet computer, one that comes closer to competing with Apple's full-sized iPad and other tablets. Here's a look at how the Nexus 10 compares with other tablets with comparable screens.Google Inc.'s Nexus 10 (available Nov. 13):—